Our Technology

Chips wear out, causing field failures

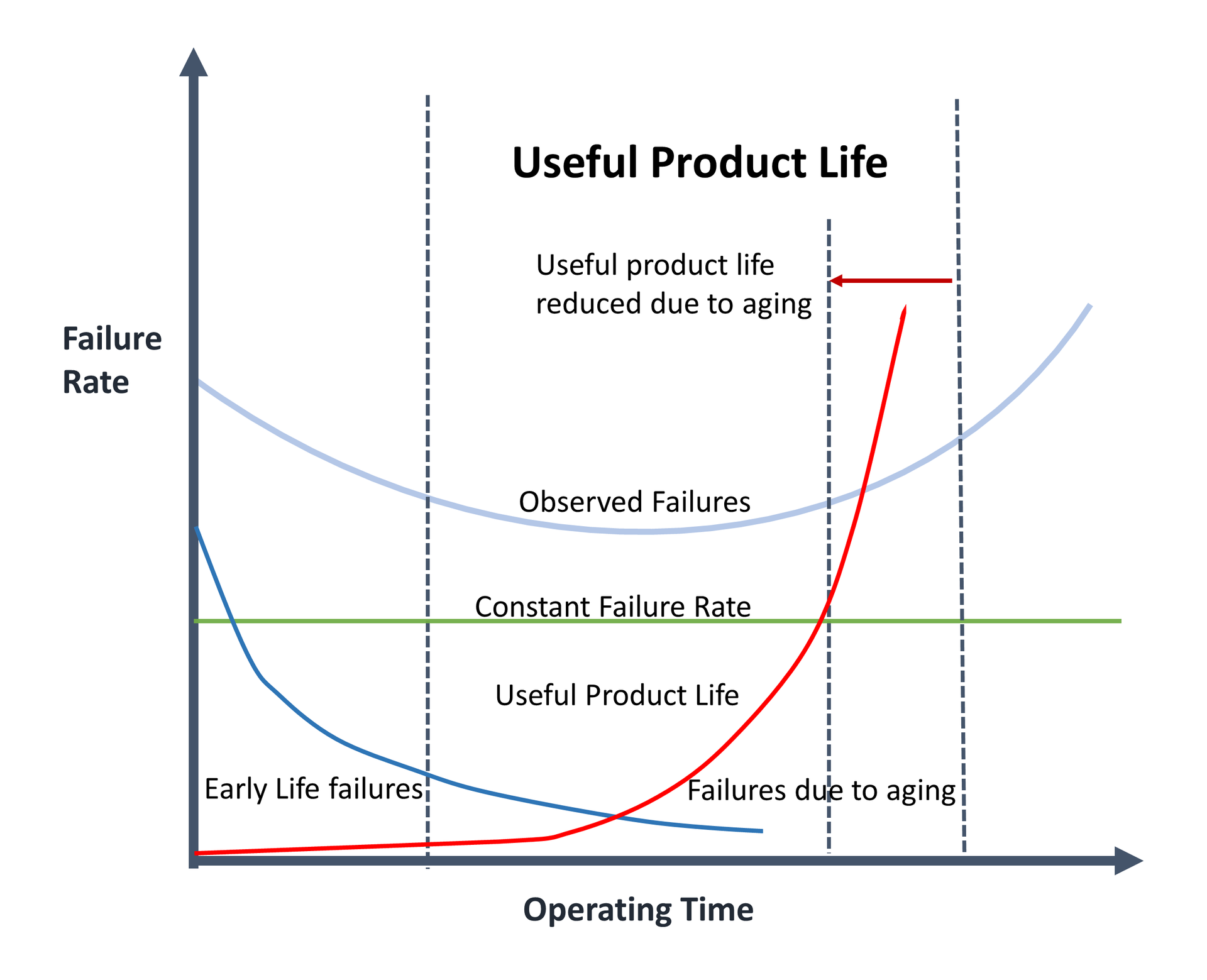

Wear-out reduces the useful life of chips that are produced using advanced semiconductor processes.

Today’s chip design methods don’t take aging into account.

Current design flows don’t account for wear-out mechanisms. And aging failures cannot be identified during manufacturing test.

Design rules and layout rules specified by a foundry assure manufacturability, but not reliability. Chip designers apply guard bands because accurate models for aging are not available for the design process of chips in advanced semiconductor processes, but guard bands will significantly reduce performance.

What’s needed is a way to predict chip failures in the field.

Transistor parameters change as a device ages, resulting in the device not operating at spec (semiconductor wear-out). In addition, wear-out causes a reduction in useful product life.

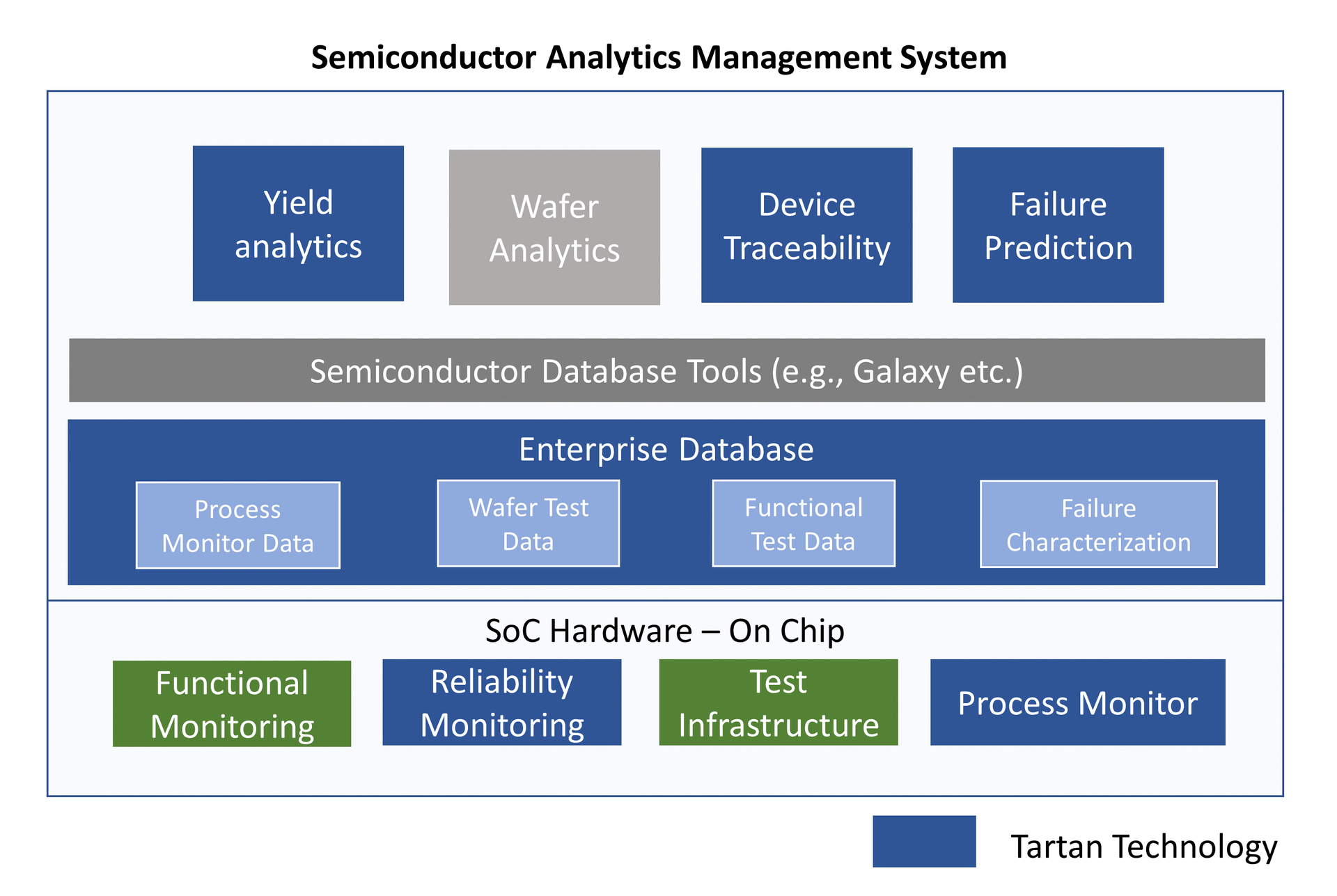

Tartan’s patented manufacturing analytics technology improves semiconductor traceability, quality, yield, and reliability.

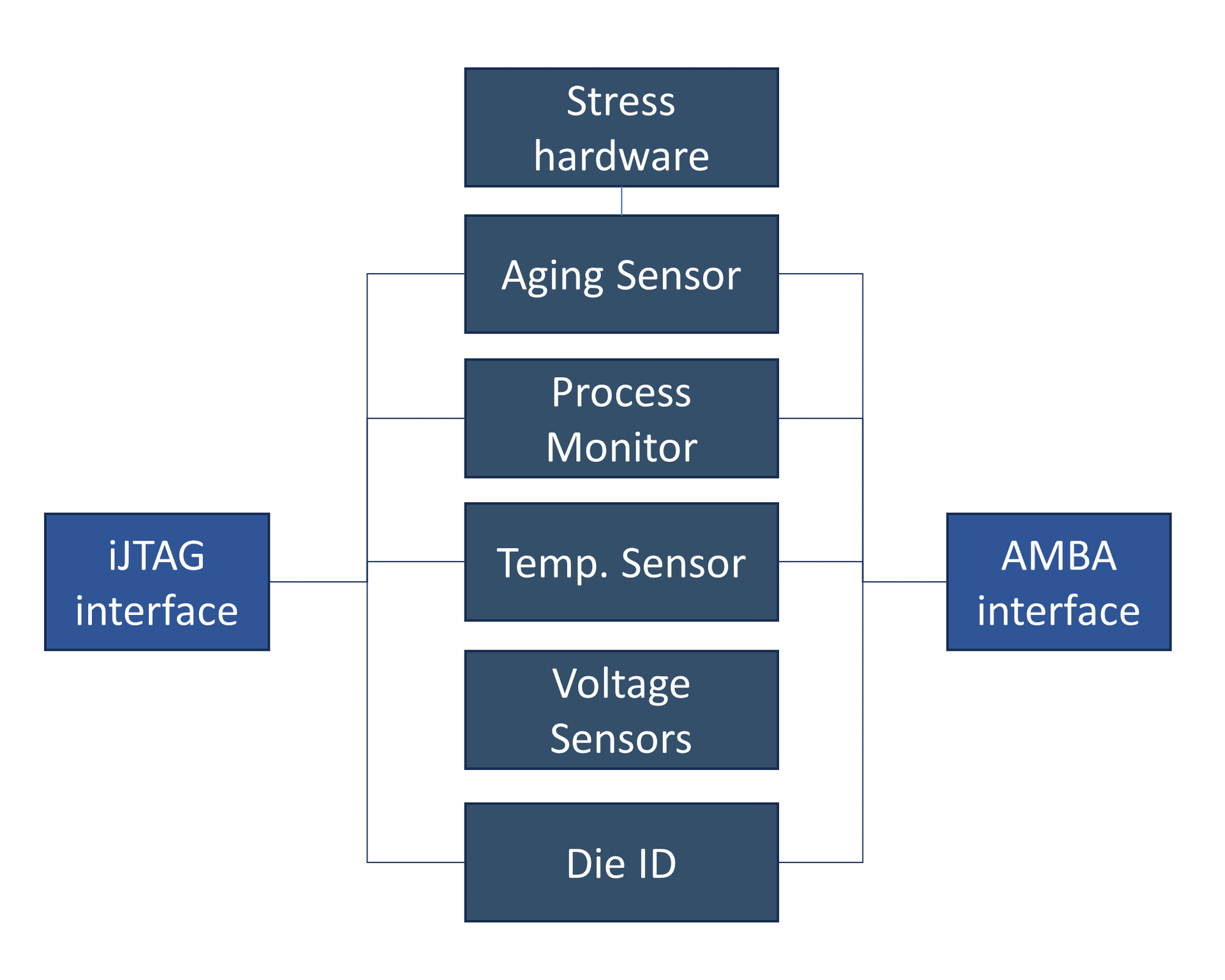

Measure Chip Manufacturing & Reliability Parameters

- Voltage sensor

- Temperature sensor

- Aging sensor

- Process control monitor

- Chip ID

Collect Manufacturing & Reliability Data

- New Product Intro services

--- Mfg test program development

--- Reliability studies

- Enterprise database

- Mfg yield and reliability

--- Yield ramp

--- Outlier detection

Data Analytics

- Analysis engines & solutions for

-- Rapid yield ramp

-- Reliability analytics

-- In-field failure prediction

Traceability

- Device traceability from wafer to field

Field Failure Prediction and Device Self-Identification for Failure

- Machine Learning model for failure

- Predictive failure inferencing in the cloud, in system, or on chip

Process/Reliability Sensor IP

With Tartan’s unique solutions, you can monitor your device’s health over its useful product life and predict failures. We enable you to capture process data per-die, during manufacture as well as device operation.

This data is then incorporated into an Enterprise Database for traceability, and application of our machine learning algorithms for reliability.

Our IP is fully compatible with current design flow methodologies. Designers can integrate Tartan’s Process/Reliability Sensor IP with their standard design flow and use standard design-for-test (DFT) tools to integrate the IP with their test infrastructure.

Data Collection and Analysis

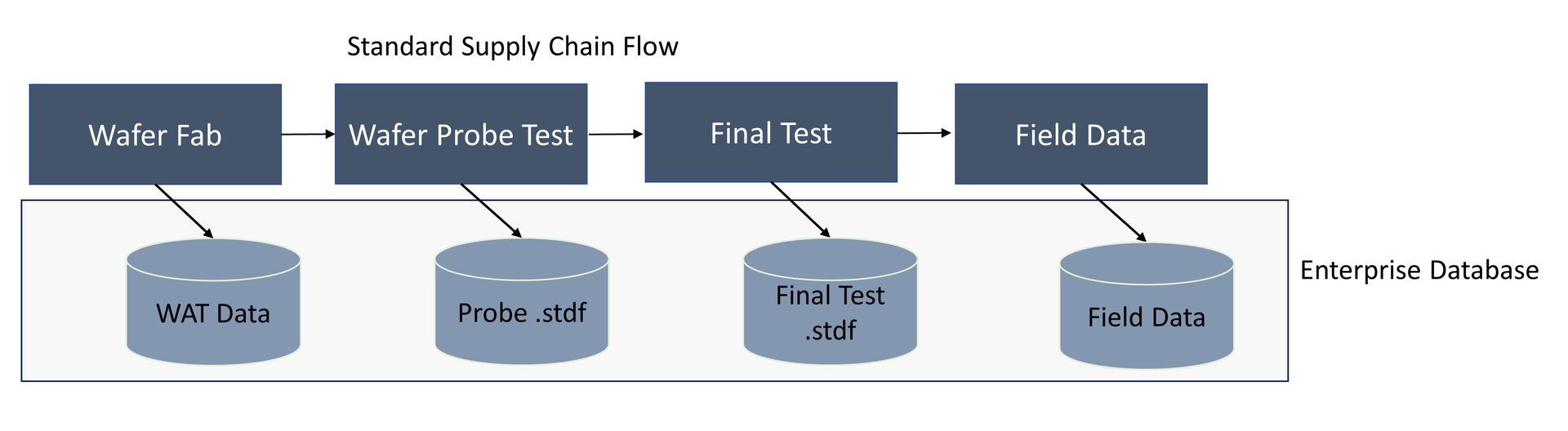

Data collection starts with developing high-quality manufacturing test and test hardware. Combining these tests with device characterization tests help confirm the performance targets over the manufacturing process range. Including characterization for failure with performance characterization provides the necessary foundation for yield, reliability and failure prediction analytics.

We build our actionable analytics capability on top of the Enterprise Database which includes manufacturing data as well as field data from our sensors.

Data Analytics

Maintaining chip quality and reliability throughout a product’s life requires data analytics to assess stability in the process, and identify manufacturing outliers and other anomalies that may occur.

This work requires linking manufacturing test data at the die level with wafer fab data.

With an integrated approach to data collection, Tartan can provide actionable analytics to rapidly ramp yield while maintaining high levels of quality and reliability throughout the chip’s life.

Tartan’s solutions enable traceability from fab to field

Traceability is required not only for proper supply chain management, but also to assure that every device in the field has been through the specified manufacturing process and passed each step.

Tartan’s manufacturing diagnostics, including failure prediction, take advantage of the required manufacturing information that is imprinted on the device.

Using the traceability features of our technology enables manufacturing analytics to be used with commercially available semiconductor manufacturing data mining tools.

Let us help you predict field failures

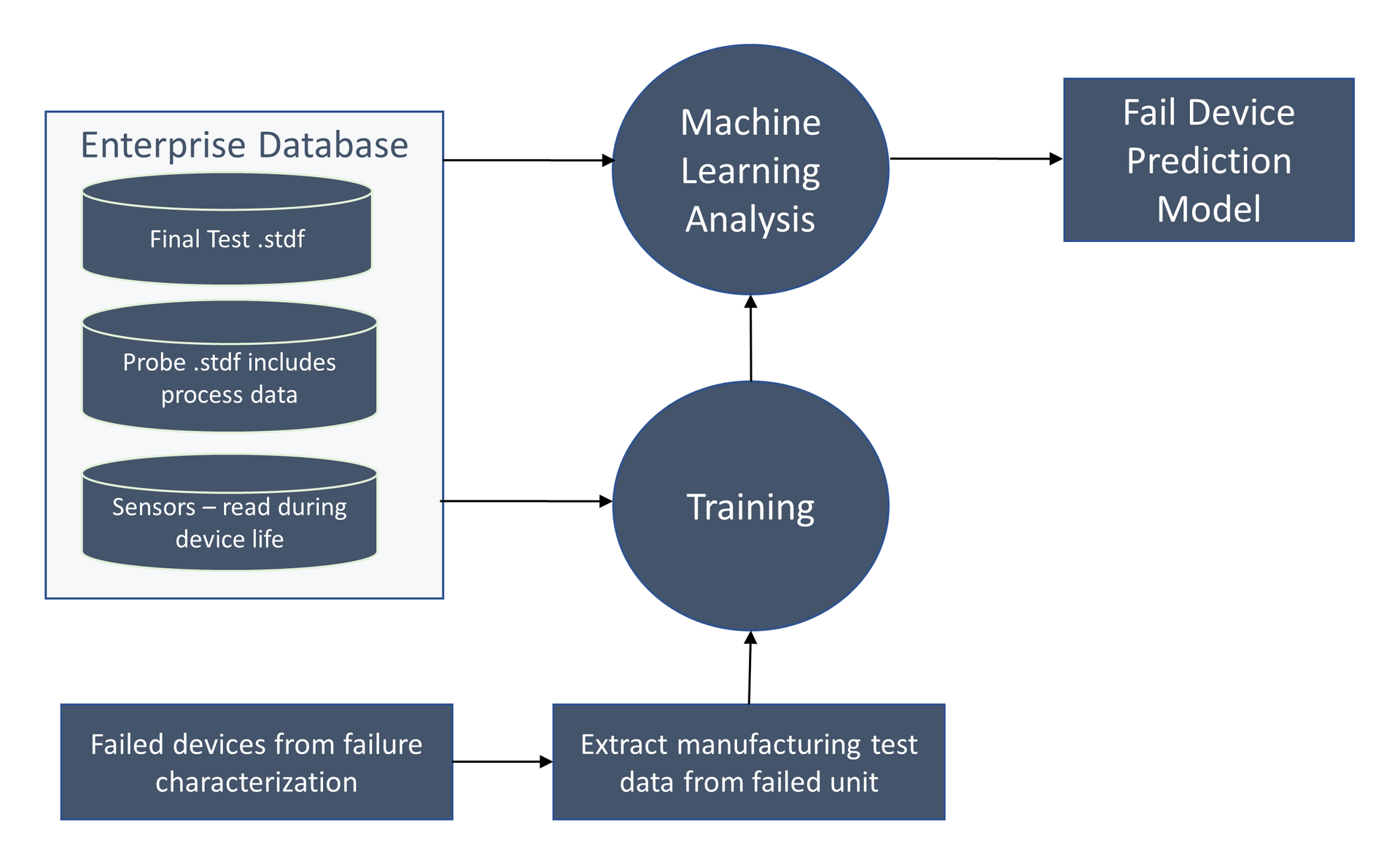

By monitoring and recording the device aging process during the operating life of a device, we can use machine learning (ML) algorithms to predict failures.

Our enterprise database along with the data collected during failure characterization enables ML training to identify failures.

With built-in traceability features, we can also provide an analysis of the risk to each unit in the field.

Self-classification for failure

Based on the results from failure prediction, Tartan provides a small app that enables the device to self-classify for potential failure.

The app requires minimal compute resources and compute cycles, making it ideal to run within the targeted system.

Tartan Silicon Systems, Inc. - All Rights Reserved